Discover what we do

Mechanical, Process & Piping Engineering

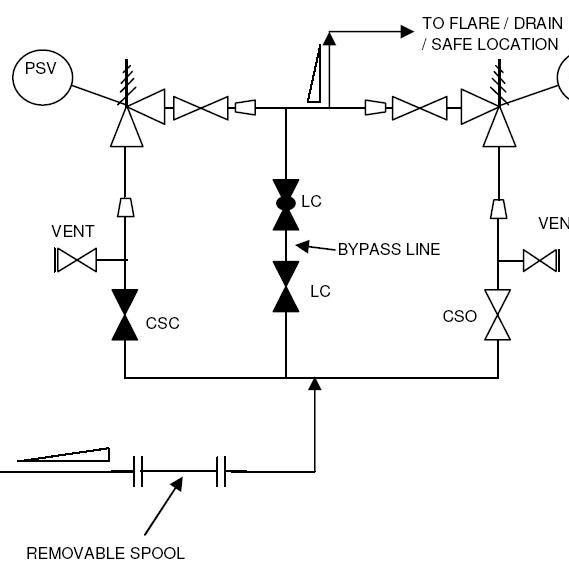

Process Safety

Risk assessment - PHA (HAZOP, What-if)

We specialize in identifying, mitigating and controlling of the risks associated

with your operation and facilitating the PHA sessions using the most effective PHA

methodologies (HAZOP and What-if analysis):

1.HAZOP (Hazard and Operability Study)

2. What-if Analysis:

We consider the potential failures and their consequences by asking "

What-if this happens" to evaluate the risks and recommend the proper Independent

Protection Layers (IPL’s) to mitigate and control the risks.

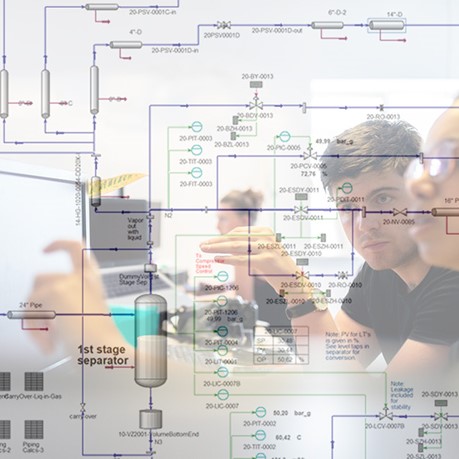

Process Engineering

- P&ID and PFD

- Process simulation by HYSYS

- Hydraulic calculation by Pipe-flo

- Heat exchanger thermal design by HTRI

- Process Control and Automation

- Pipe, pump and valve sizing

- Conducting PHA (Process Hazard Analysis)

- HAZOP, What-if

- Design and optimize the industrial cooling systems (chiller, cooling tower)

- Design and optimize the heating system (Steam, Hot oil)

Process Automation

Logic control, functional description, PLC programming

We specialize in transforming your manual operations through cuttingedge process automation. Whether you're in manufacturing, chemicals, pharmaceuticals,

or energy, our engineering expertise empowers your business to achieve unparalleled safety

and performance.

Expertise Includes:

• Control System Design & Integration

• SCADA & PLC Programming

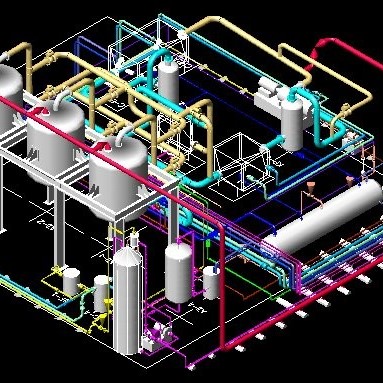

Preliminary and detailed engineering

- Conceptualization and planning

- Preparation and authentication of engineering documents, including:

• P&IDs

• 3D and 2D models

• General arrangement drawings

• Shop drawings

• Plot Plans

• ISOs

• As-built drawings

Mechanical Engineering

- Utilizing leading software platforms such as Solidworks, Inventor, and Revit

- HVAC design

Piping Engineering

- Preparation of piping material specifications (PMS)

- Stress analysis using software like CAESAR II

Industrial cooling and Refrigeration

Batch reactor design and optimization

Our services include:

- Batch Reactor Design & Engineering: From lab-scale to large-scale systems, we

design reactors optimized for your specific reactions, including heat and mass

transfer analysis, and reaction kinetics.

- Process Modeling & Simulation: Using state-of-the-art software, we simulate

reactor performance to predict outcomes, troubleshoot potential issues, and finetune design before implementation.

- Retrofit & Optimization: Already have a batch reactor? We can enhance your

existing system, optimizing for throughput, energy use, and product quality

Structural Design

- Finite element analysis

- Design optimization

- Compliance with industry standards and regulations

Energy efficiency and optimization

Project cost estimate and Feasibility study

Project Management & Execution

Water & Wastewater Treatment

Protect the environment and optimize your operations with expert industrial wastewater treatment solutions

Sequencing Batch Reactor (SBR)

The SBR process is a highly effective, batch-based treatment system that's ideal for handling variable loads and a wide range of industrial effluents. We design and implement SBR systems that provide excellent nutrient removal, flexible operation, and energy efficiency, while allowing for precise control over the treatment process. Perfect for industries that need to meet stringent effluent standards.

Membrane Bioreactors (MBR)

Combining biological treatment with membrane filtration for superior effluent quality and water recovery.

Deionized water

Design, Optimization, Manufacturing, Installation

Physico-chemical wastewater treatment system

Biological treatment, Coagulation and Flocculation

Filtration

Activated carbon filtration

- Design, Optimization, Manufacturing, Installation

- Removal of organic pollutants, heavy metals and color as well as odor control

Desiccant Solutions

Air & Process Filtration